Paver Block Making Machine Setup

Price 185000.0 INR/ Unit

Paver Block Making Machine Setup Specification

- Product Type

- Paver Block Making Machine

- General Use

- Industrial

- Method

- Other

- Processing

- Other

- Automatic

- Yes

- Voltage

- 110-215 Volt (v)

- Capacity

- 5000 Pcs/hr

- Weight (kg)

- 2 Tonne

- Warranty

- 1 year

- Type

- AAC Block Machine

Paver Block Making Machine Setup Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Paver Block Making Machine Setup

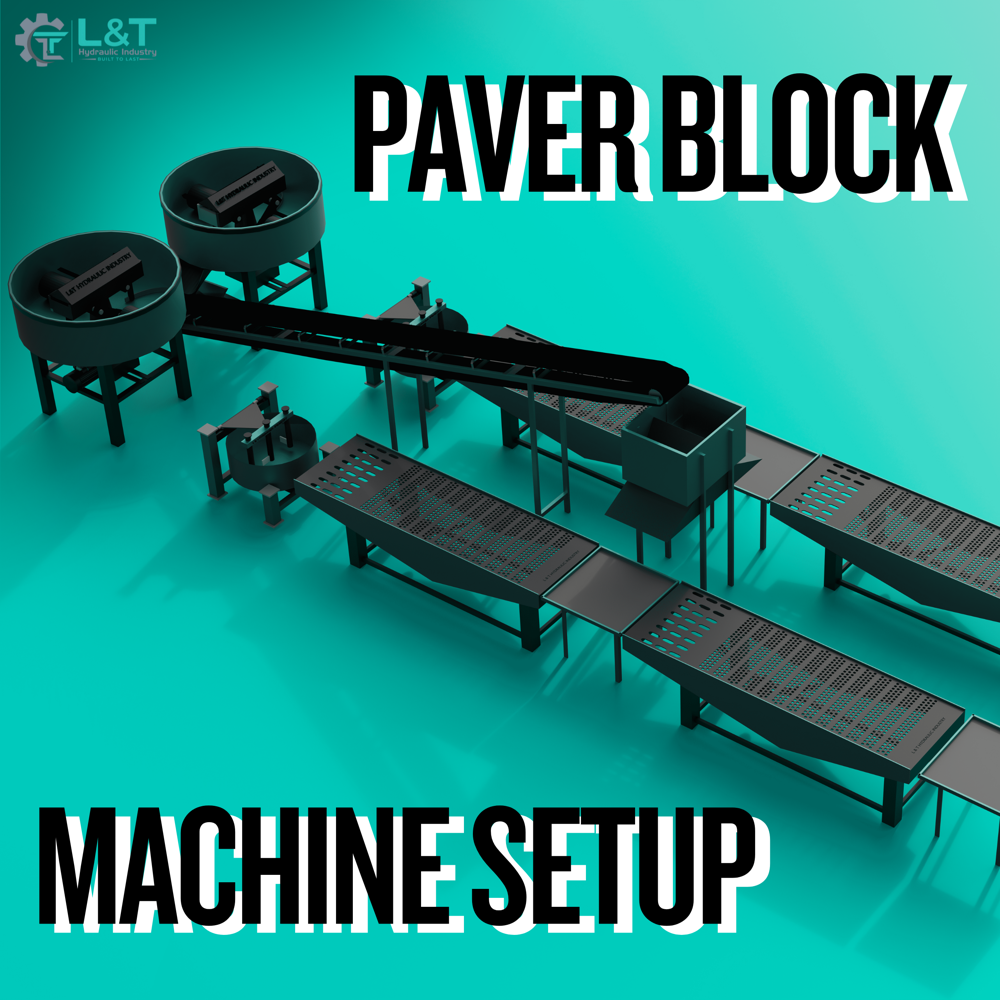

Product Description Paver Block Making Machine Setup | L&T Hydraulic Industry

L&T Hydraulic Industry proudly presents a high-performance Paver Block Making Machine Setup designed for maximum productivity, durability, and precision. Our setup is a complete solution for manufacturing interlocking paver blocks, designer tiles, and concrete blocks with superior finish and strength.

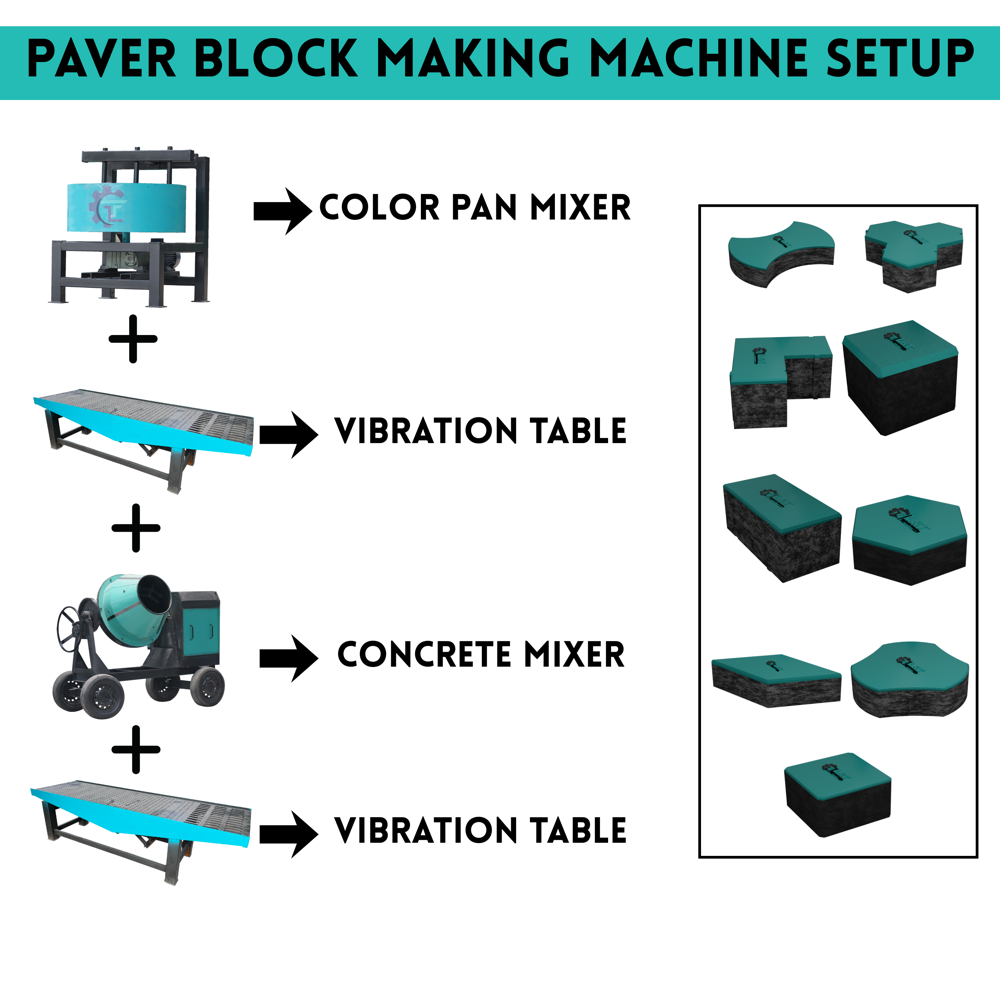

This advanced setup includes:

-

1 Concrete Mixer: Ensures uniform mixing of cement, sand, and aggregates for consistent block quality.

-

1 Color Pan Mixer: Perfect for producing vibrant, high-quality color layers for designer tiles and paver blocks.

-

2 High-Performance Vibration Tables: Engineered with powerful vibration motors to ensure uniform compaction, smooth surface finish, and enhanced block strength.

Key Features:

-

Robust Hydraulic Technology: Built with state-of-the-art hydraulic systems for seamless operation and longer machine life.

-

High Production Capacity: Designed to deliver large-scale output suitable for both small and medium-scale industries.

-

Durable Construction: Heavy-duty frame and precision-engineered components ensure long-lasting performance even under continuous operation.

-

Energy Efficient: Low power consumption with maximum productivity reducing operational costs significantly.

-

Low Maintenance: Simple design with easily replaceable parts for smooth, hassle-free maintenance.

-

User-Friendly Operation: Easy to operate and suitable for new entrepreneurs as well as established manufacturers.

Applications:

-

Interlocking Paver Blocks

-

Concrete Blocks

-

Designer Floor Tiles

-

Parking Tiles

-

Zig-Zag and I-Shape Pavers

Why Choose L&T Hydraulic Industry?

With years of expertise in the construction machinery industry, L&T Hydraulic Industry is known for manufacturing premium-quality, fully and semi-automatic hydraulic machines that meet the highest standards of performance and reliability. Our machines are trusted by customers across India for their efficiency, strength, and durability.

We also provide complete installation support, operator training, and after-sales service to ensure smooth machine operation and consistent output.

Technical Details (Customizable as per clients requirement):

-

Production Capacity: Up to 4,0005,000 paver blocks per shift (depending on mold design)

-

Power Requirement: 1015 HP (approx.)

-

Operation Mode: Semi-Automatic / Manual

-

Material Used: MS Steel with Anti-Corrosive Coating

-

Warranty: 1 Year (against manufacturing defects)

Contact Us:

L&T Hydraulic Industry

Manufacturer & Exporter of Fly Ash Brick Making Machines, Paver Block Machines, Concrete Mixers & Construction Equipment.

For more information or quotation, feel free to contact our sales team today.

Streamlined Block Manufacturing

With the AAC Block Machine setup, industrial users can quickly and efficiently produce paver and AAC blocks. This equipment, though not automatic, ensures consistent results while allowing for operational control, making it ideal for diverse Indian manufacturers and construction projects.

Flexible Voltage Compatibility

Operating at 110215 volts, this AAC Block Machine adapts seamlessly to standard industrial electrical supplies across India. Whether you are upgrading an existing plant or establishing a new one, this flexibility makes installation straightforward.

Reliable After-sale Support

The one-year warranty on this AAC Block Machine ensures peace of mind for buyers. As supplied by prominent Indian manufacturers, suppliers, and traders, customers can access timely maintenance, support, and spare parts as needed.

FAQs of Paver Block Making Machine Setup:

Q: How is the AAC Block Machine installed for industrial use?

A: Setting up the AAC Block Machine involves positioning it on a level surface, connecting it to a power supply within the 110215 volt range, and ensuring all safety features are functional. It is recommended to have a skilled technician oversee the initial installation.Q: What is the main benefit of using this non-automatic AAC Block Machine for paver block production?

A: The key advantage is its cost-effectiveness and operational control. As a non-automatic model, it provides flexibility for manual adjustments and reduces dependency on complex electronics, making it easier to maintain.Q: When should the machine be serviced during its warranty period?

A: Regular servicing is recommended every six months, or sooner if the machine sees heavy use. Sticking to a maintenance schedule helps to maximize the machines efficiency and durability within the one-year warranty.Q: Where can I purchase this AAC Block Machine in India?

A: These machines are available through reputable manufacturers, suppliers, and traders across India. Many offer both sales and after-sales support, making it convenient to source and maintain locally.Q: What process does the AAC Block Machine follow to create paver blocks?

A: Raw materials are mixed manually and poured into molds, which are then compacted and cured in the machine. Although the machine is not automatic, it ensures uniformity in block size and strength, following standardized industrial protocols.Q: How is the machine used efficiently by operators?

A: Operators should follow the manufacturers guidelines for loading materials, operating the controls, and conducting routine inspections. Adequate training ensures the machine runs smoothly, minimizing downtime and maximizing output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paver Block Making Machine Setup Category

Vibration Table

Price 40000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Power : 7.5 kW Watt (w)

General Use : Industrial

Color : Multiple

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese